Heat Exchanger Plates for Refinery Industry

GEA VT20 Plate Heat Exchanger Plates with SS304/SS316 Company Profile Shanghai Empire Mechanical Engineering Co., Ltd. i

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | GEA NT Series |

| Customized | Non-Customized |

| Certification | ISO |

| Sectional Shape | Rectangle |

| Performance | Pressure Resistant, Temperature Resistant, Corrosion Resistant |

| Material | Stainless Steel |

| Plate Material | 304ss, 316ss, Titanium, Asmo254, Hastelloy, Ni201 |

| Plate Hole | 0 Hole, 1 Hole, 2 Holes, 3 Holes, 4 Holes |

| Gasket Material | NBR, EPDM, HNBR, Viton,Neoprene |

| Gasket Type | Glued, Clip-on, Button-Lock |

| Delivery Time | Within 10 Working Days |

| Style | Plate |

| Transport Package | Standard Export Plywood Case & Customizing |

| Specification | 0.5mm, 0.6mm |

| Trademark | DG or OEM |

| Origin | China |

| HS Code | 84199090 |

| Production Capacity | 200000m2/Year |

Product Description

GEA VT20 Plate Heat Exchanger Plates with SS304/SS316Company Profile

Shanghai Empire Mechanical Engineering is specialized in manufacuturing plate heat exchanger,

plate and shell heat exchanger,plate heat exchanger plate,plate heat exchanger gasket and hydraulic press for forming plate.We can also provide plate heat exchanger mould,semi-welded plate heat exchanger,wide gap/free-flow plate heat exchanger.

Products Description

Channels of VT20 are formed between the plates and the corner ports are arranged so that the two media flow through alternate channels. The heat is transferred through the plate between the channels, and complete counter-current flow is created for highest possible efficiency. The corrugation of the plates provides the passage between the plates, supports each plate against the adjacent one and enhances the turbulence, resulting in efficient heat transfer.

| PHE Plate Specifications | |

| Model | VT20 lock-in |

| Material | 304SS,316SS,Titanium,ASMO254,Hastelloy C-276,Ni201,904L |

| Thickness | 0.5mm,0.6mm |

| Plate Hole | 0 Hole,1 Hole,2 Holes,3 Holes,4 Holes |

| Replacement Brand | GEA |

| Package details | Standard export plywood case & customizing |

| Production Capacity | 200000m²/year |

Our Advantages

a. can provide various phe plates for all makes and models,and also make plate mould according to

customer requirements.

b. are supplier of phe replacement plates for ,GEA,Tranter,Sondex,Funke,Thermowave,APV.

c. not only produce conventional plates, but also special plates, such as semi-welded,free-flow,double-wall plates.

d. designing and calculating new PHE according to technical specification provided by customers in different

industry conditions.

e. high quality,reasonable price,fast delivery.

f. We are the source of goods,keep sizable inventory of gaskets & plates to ensure delivery time.

g. ISO9001 & ISO14001

Providing Plate and Gasket for Full Makes

| Brands | Type | Replacement Plates Model |

| Al | M Series | M3/M6B/M6M/M10B/M10M/M15B/M15M/M30/MA30M /MA30S/MA30W/MS6/MS10 |

| Clipline | Clip3/Clip6/Clip8/Clip10/Clip15 | |

| T Series | TS6M/TS20M/TL6B/TL10P/T20M/T20P/T20S/T2B/T5B/T5M /T8B/T8M/T35P/T45M/T50M/TL35B/TL3/TS6M/TS35P/TL15B /TL20P/TS50M/ | |

| P Series | P1/P2/P5/P12/P13/P14/P15/P16/P17/P20/P22/P26/P30/P31/P32/P36/P41/P45 | |

| A Series | A3/A10/A10B-A/A15/A15B/A20/A20B/AK20/A30/A35/AX30 /AM10B/AM15B/AM20/AX30 | |

| GEA | NT Series | NT100T/NT100M/NT100XNT150S/NT150LNT250S/NT250M /NT250LNT350S/NT350M/NT50L/NT50T/NT50M/NT50X |

| VT Series | VT04/VT10/VT20lock-in/VT20P/VT40lock-in/VT80M | |

| FUNKE | FP Series | FP02/FP04/FP05/FP08/FP10/FP12/FP14/FP16/FP20/FP22 /FP31/FP40/FP41/FP50/FP60/FP80/FP225 |

| Tranter | GX Series | GX6/GX12/GX18/GX26/GX37/GX42/GX51/GX60/GX64/GX85 /GX91/GX100 |

| GC Series | GC18/GC26/GC51/GC60 | |

| Others | GL12/GL13/S3/UX01/UX05/UX20/UX40 | |

| Sondex | S Series | S4A/S7A/S8A/S9A/S14A/S19A/S21A/S31A S21/S22/S37/S42/S43/S62/S65/S81/S121/SM3/S113/S100 |

| Vicarb | V Series | V2/V4/V8/V13/V20/V28/V45/V60/V85/V100/V110/V130/V170 /V180/V205 |

| Thermowave | PP Series | TL90PP/TL150PP/TL250PP/TL400PP/TL450PP/TL500PP /TL650PP/TL850PP |

| SS Series | TL90SS/TL150SS/TL250SS/TL400SS/TL450SS/TL500SS /TL650SS/TL850SS | |

| APV | H17/N35/B063/A055/A085/Q080/T107/T14/SR1/SR2/SR3 | |

| Special Plate | Double Wall/Semi-Welded/Free Flow | |

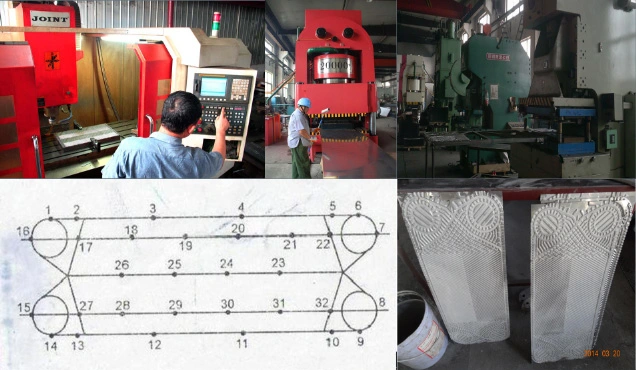

Production Line

Making plate mould -Pressing replacement plates-Punching plate holes

-Testing plate corrugation depth- Testing plate crack-Assembling PHE

Quality check

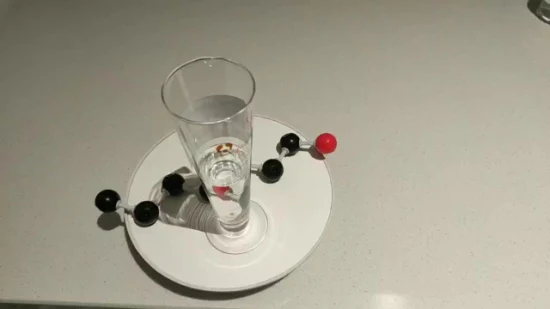

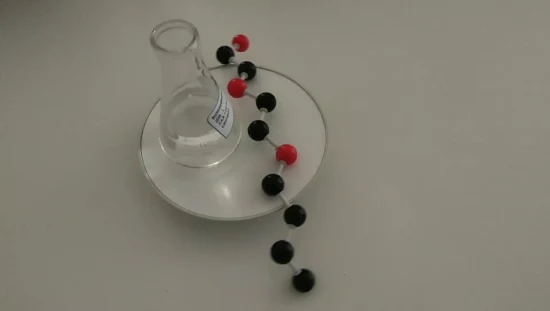

Plate testing:

First, testing plate corrugation depth (free channel).Use micrometer (the best digital displayer) to test 32 sites of plate.Second, testing plate crack.The method is dye check. Spraying display agent (white) on one side of plate,the other side of plate sprays penetrant (red) , if penetrant passes through plate and the side of display agent is dyed red, it shows the plate has crack, the method is very simple and efficient.

Shipping & Packing

Delivery time: Within 10 working days after received the deposit and confirmed all details.

Package details: Standard export plywood case & customizing

Related Products

-

![ASTM Standard A276 410 420 416 Stainless Steel Round Bar Rod ASTM Stainless Steel Bar]()

ASTM Standard A276 410 420 416 Stainless Steel Round Bar Rod ASTM Stainless Steel Bar

-

![Best Selling Surfactant Fatty Alcohol Polyoxyethylene Ether Moa-7/Aeo-7 with Good Price]()

Best Selling Surfactant Fatty Alcohol Polyoxyethylene Ether Moa-7/Aeo-7 with Good Price

-

![Antifoaming Agent Dr-8038 for Water-Based Inks (high-gloss)]()

Antifoaming Agent Dr-8038 for Water-Based Inks (high-gloss)

-

![Good Organic Raw Material CAS No: 20324-33-8 Tripropylene Glycol Monomethyl Ether for Paint]()

Good Organic Raw Material CAS No: 20324-33-8 Tripropylene Glycol Monomethyl Ether for Paint