Formaldehyde Free Non-Iron Finishing Resin Rg-220h

Formaldehyde-free No-ironing Resin RG-220H Main ingredient: Modified dimethyl dihydroxyvinyl urea. Physical and chemical

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | Formaldehyde Free Non-Iron Finishing Resin Rg-220h |

| Density | 1.20-1.22g/cm3 |

| pH | 4.0-5.5 |

| Solid Content | 40-50% |

| Transport Package | 150kgs / Exporting Standard Plastic Drum |

| Specification | Inoicity: non-ionic |

| Trademark | RG |

| Origin | Weifang, China |

| HS Code | 39091000 |

| Production Capacity | 50000mt/Year |

Product Description

Formaldehyde-free No-ironing Resin RG-220HMain ingredient:

Modified dimethyl dihydroxyvinyl urea.

Physical and chemical index:

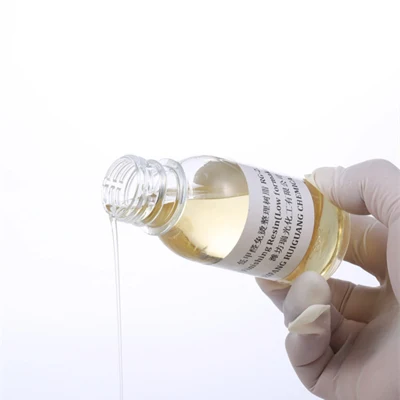

Appearance: Clear yellowish liquid

Ionicity: Nonionic

PH Value: 4.0-5.5

Solid content: 40-45%

Solubility: Soluble in water

Application:

It's easy-care, non-ironing finishing crosslink agent, apply to cotton, viscose, and their blended fabric anti-wrinkle and anti-shrink treatment. It also could be used in emboss, Schreiner and calendar finishing.

The fabrics treated by this product with good no-iron performance, good hydrolytic stability, and chlorine resistance.

It's durable for laundry and dry wash. None formaldehyde emission.

Usage:

Padding at indoor temperature, mangle expression is 60-90%, dosage as below:

| Fabrics | Cotton | Viscose | T/C | T/R |

| RG-220H (g/L) | 40-120 | 80-180 | 30-100 | 50-150 |

The dosage of catalyst RGF-M between 20-50g/L.

Package and Storage:

Packed in 25kgs,50kgs, 160kgs plastic drum.

12 months shelf life stored at a cool and ventilated place in 5-30ºC.

Reference Formula:

1, Fabric for the T-shirt(Woven cotton):

60-120 g/L Resin RG-220H

21-36 g/L Catalyst RGF-M

1-3 g/L Penetrant(Content 100%)

20-30 g/L Strength protector RG-YL25

10-30 g/L Softener RG-QD30

Mangle expression: 70%

Pre drying: Normal process, dry to 5-8% moisture

Drying temperature: 150ºC,3 minutes or 170ºC,30 seconds

2, Viscose fabric(Artificial cotton):

120-180 g/L Resin RG-220H

36-50 g/L Catalyst RGF-M

1-3 g/L Penetrant(Content 100%)

20-30 g/L Strength protector RG-YL25

10-20 g/L Softener RG-QD30

Mangle expression: 80%

Pre drying: Normal process, dry to 5-8% moisture

Drying temperature: 170-175ºC,30 seconds

3, Fabric for the coat(Cotton):

40-80 g/L Resin RG-220H

20-28 g/L Catalyst RGF-M

1-3 g/L Penetrant(Content 100%)

20-30 g/L Strength protector RG-YL25

10-20 g/L Softener RG-QD30

Mangle expression: 70%

Pre drying: Normal process.

Drying temperature: 170ºC,30 seconds.